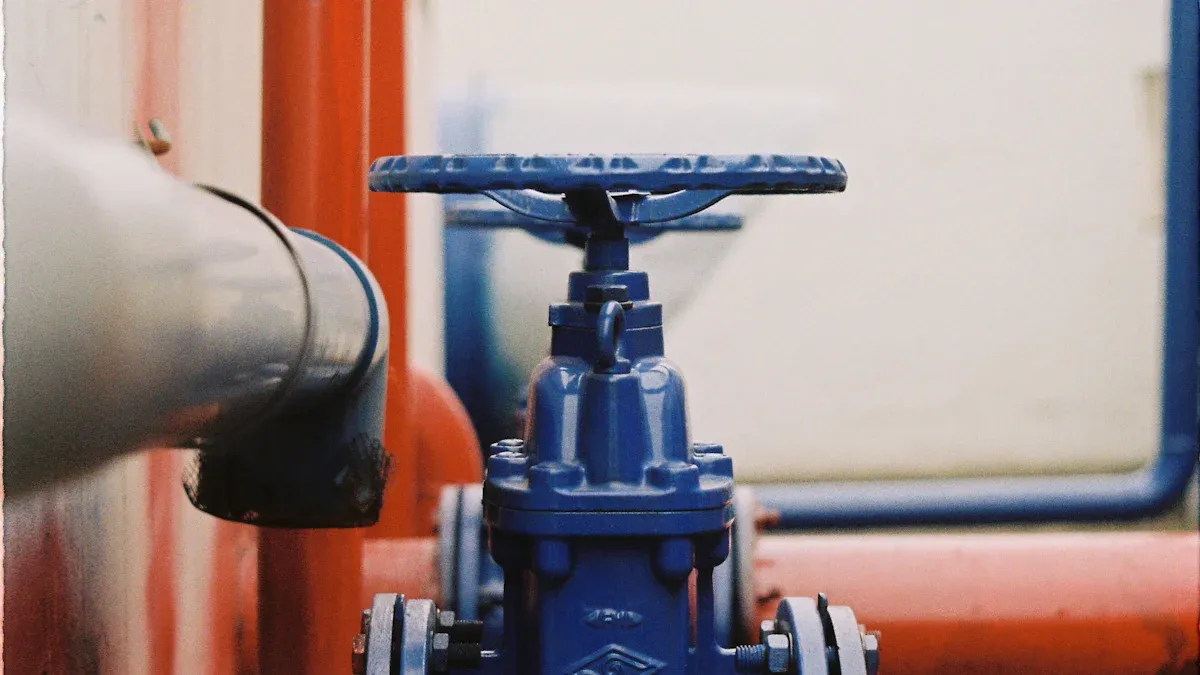

A gate valve is a machine part that controls flow. It does this by moving a gate up or down inside the valve. This valve lets water or other liquids move through easily. It does not slow down the flow much. This makes it good for stopping or starting flow in pipes. Gate valves are very important in city and factory systems.

| Valve Type | Function | Usage Percentage |

|---|---|---|

| Gate Valves | On/off control | Approximately 20% |

| Butterfly Valves | Flow regulation | 25% |

| Ball Valves | Precise control | 15% |

| Check Valves | Prevent backflow | 20% |

| Diaphragm Valves | Corrosive resistance | 20% |

Gate valves are still needed in water systems. They give a strong shutoff and have a wide opening. This helps keep the pressure drop very low.

Gate valves work by moving a gate up or down. This opens or closes pipes all the way. They are good for stopping or starting liquid flow fast. They do not slow down the flow.

There are two main types of gate valves. Rising stem valves show if they are open or closed. Non-rising stem valves save space. But they need extra signs to show their position.

Gate valves should be fully open or closed. This helps avoid damage. They are used in water, oil, and factories. They seal well and last a long time.

A gate valve is a kind of valve that uses a flat or wedge-shaped gate to stop or let liquids flow. The gate moves up to open or down to close the pipe. The main job of a gate valve is to shut off flow very well. People use this valve in water systems, oil pipes, and many factories.

The main parts of a gate valve are:

The body holds the inside parts and connects to the pipe.

The bonnet covers the top and lets workers fix the valve.

The gate or disc moves to block or let liquid pass.

The seat helps the gate seal tightly when closed.

The stem links the gate to the handle or actuator.

These parts work together to make the valve strong and dependable. Gate valves come in many sizes and can handle many kinds of liquids.

A gate valve works in a simple way. The gate inside moves straight up and down. When someone turns the handwheel or actuator, the stem moves the gate. If the gate goes up, the valve opens and liquid flows. If the gate goes down, it presses on the seat and stops the flow.

There are two main types of stems in gate valves:

Rising stem: The stem moves up and down with the gate. You can see if the valve is open or closed. It is easier to fix because the threads are outside.

Non-rising stem: The stem stays in place while the gate moves inside. This saves space and fits in small spots, but you cannot see the valve position as easily.

| Feature | Rising Stem Gate Valve | Non-Rising Stem Gate Valve |

|---|---|---|

| Stem Movement | Stem rises above valve body, easy to see status | Stem stays inside, saves space |

| Maintenance | Easier, threads are accessible | Harder, threads are inside |

| Space Needed | Needs more vertical space | Compact, fits in small spaces |

| Visual Position | Easy to see open/close | Needs extra indicator |

A gate valve is not made for controlling flow. If you use it for partial flow, the gate and seat can wear out fast. The best way to use this valve is to keep it all the way open or closed.

Gate valves have many features that make them useful:

The flow path is straight, so liquid moves easily and pressure drop is low.

The gate presses hard on the seat, so it seals well and stops leaks.

It can block flow from both directions.

There are many material choices like cast iron, stainless steel, carbon steel, bronze, plastic, and alloys. Alloys are strong and do not rust easily.

Tip: Alloys are picked for small valves in low-pressure jobs because they do not rust and are easy to make.

Gate valves are best for shutting off flow. They work well when you need to stop or start flow completely. They are not good for adjusting flow. If you leave a gate valve partly open, the gate can shake and the seat can get ruined. That is why people use globe valves or ball valves to control flow instead.

| Valve Type | Flow Path Characteristics | Pressure Drop | Flow Control Capability | Typical Use Cases |

|---|---|---|---|---|

| Gate Valve | Straight-through | Low | Not for throttling | On/off, isolation |

| Globe Valve | Changes direction | High | Good for throttling | Flow control |

| Ball Valve | Quarter-turn, straight | Low | Limited throttling | Fast shutoff |

Gate valves are still a top pick for shutting off flow in water, oil, and factory systems. Their simple build, strong shutoff, and many material choices make them a good choice for many jobs.

There are many kinds of gate valves for different uses. The two main types are rising stem and non-rising stem gate valves. Rising stem gate valves let you see if they are open or closed. The stem moves up when open and down when closed. Non-rising stem gate valves save space because the stem does not move up. Both types help control flow in pipes.

| Feature | Rising Stem Gate Valve | Non-Rising Stem Gate Valve |

|---|---|---|

| Visual Indicator | Shows if open or closed | Needs a marker or watch the handle |

| Maintenance | Easier, stem is outside | Harder, stem is inside |

| Space Needed | Needs more room above | Fits in small spaces |

| Cost | Costs more | Costs less |

| Typical Use | Used in oil, gas, and power plants | Used in water and building systems |

Other types are wedge gate valves, parallel slide gate valves, and knife gate valves. Wedge gate valves use a wedge-shaped disk to close tightly. Parallel slide gate valves have two disks and work well with high pressure. Knife gate valves have a sharp edge to cut thick liquids or slurries. Sometimes, people call a gate valve a sluice valve, mostly in water systems.

Flanged and threaded gate valves connect to pipes in different ways. Flanged valves use bolts and gaskets for a strong seal in big pipes. Threaded valves screw into smaller pipes and are easy to put in.

Gate valves are used in many fields. Oil and gas companies use them in pipes and tanks. They work well with high pressure and seal tightly. Water plants use gate valves to control water flow and levels. Power plants use them for steam and cooling water. Mining uses knife gate valves for thick liquids and waste water. Chemical factories use gate valves because they seal well and resist rust.

Gate valves can handle higher pressure than butterfly valves. They also seal better. Ball valves shut off fast but cost more when they are big. Gate valves open all the way, so water or oil flows easily with almost no pressure drop.

Gate valves have many good points:

The full opening lets liquid move freely.

They seal tightly to stop leaks.

They work both ways in a pipe.

They last long and are not too expensive for big jobs.

They do not need much care.

Note: Gate valves are not good for adjusting flow. They work best when fully open or fully closed.

Some problems are that they open and close slowly and can be harder to fix. Knife gate valves are good for thick or dirty liquids but need careful use. Even with these issues, gate valves are still a top pick for stopping flow in many systems.

A gate valve can stop flow very well in many systems. It is good for blocking water or other liquids.

Picking the best valve means looking at its type, what it is made of, its size, and the rules it must follow.

Checking the valve often and putting it in the right way helps it last longer. This also keeps it safe to use in water, oil, and factory pipes.

A gate valve stops or starts the flow of liquid in a pipe. It works best for full open or full closed positions.

No, a gate valve does not control flow rate well. It should not be used for throttling because this can damage the valve.

People install gate valves in water supply lines, oil pipelines, and industrial systems. These valves help isolate sections for maintenance or repair.